Call Anytime

-

-

Send Email

sales@nitroairengineers.com

PSA Oxygen Generators

Oxidizing gas used for life sustaining and performance optimization applications Oxygen is a colorless, odourless reactive gas and the life-supporting component of air. It’s use as a respiratory gas for healthcare application, Oxygen has strong oxidizing properties that can benefit many industries by improving yields with optimize performance. Oxygen enrichment or replacement of air also enhances chemical and biological process efficiency.

Oxygen Concentrator

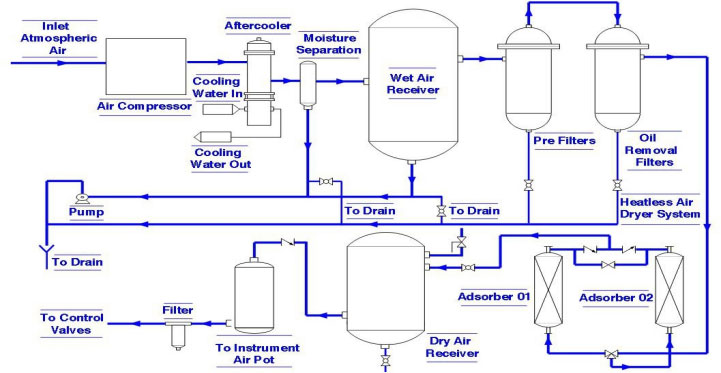

- Pre Filter + Oil Filter + Air Dryer – With Auto Drain

- Pressure Swing Adsorption [PSA] Oxygen Concentrator

- High Pressure Zeolite Molecular Sieves [ZMS]-6 – 8 bar

- High Strength, Friction & Abrasive Resistant ZMS

- Longer Operation Life- 4 – 6 years

- Surge Tank for Stabilization & Purity

- PLC Bases Operation - Precise Timing Control

- Pneumatically Operating High Speed Solenoid

PSA oxygen generators uses Pressure Swing Adsorption technology. Atmospheric air comprises of 20-21% oxygen and the PSA process utilizes Zeolite molecular sieves to extract this Oxygen from air. Oxygen at 95% is delivered, while the nitrogen adsorbed by the molecular sieves is vented back into air through the exhaust valve. Generally Oxygen generators depends on mainly four technical facts

• Flow range : PSA Oxygen generators are suitable for flows from 1 nm3/hr to 200 nm3/hr.

• Oxygen Purity : Purity of 95% is easily achievable by PSA oxygen generators, with balance mostly being a mix of inert gases such as nitrogen and argon. While this purity is suitable for many applications such as water purification, furnace enrichment, it may not be suitable for applications where 99% purity is a must.

• Pressure : PSA oxygen generators can deliver oxygen directly at 5 kg/cm2g pressure without an additional booster, making is suitable for most applications.

• Dew Point : PSA oxygen plant deliver very dry gas, with dew point as low as (-) 40°C. We also Provide measuring instruments for online detection of gas dryness with our make.

| Points of Comparison | Industrial Oxygen Plant | Medical/Commercial Oxygen Generator | |

|---|---|---|---|

| Technology | Industrial | Medical/Commercial | |

| Suitable / Recommended For | Above 2.0 Nm3/hr [ 30 LPM] | Up to 1.2 Nm3/hr [20] | |

| Operation | Continues 24 x 7 x 365 | Moderate | |

| Oxygen Purity | not less than 93 % | 85 - 90 % | |

| Oxygen Feed Pressure | 1.2 - 1.5 Kg/cm2 | 0.5 Kg/cm2 | |

| Operation Controlled | Programmable Logic Control [PLC] | Digital Circuit | |

| Oxygen Consistency | All the time | Gradually Reduces | |

| Oxygen Purity Monitoring, Display & Control | Online continuous Monitoring & Display | No monitoring & Display | |

| Life of consumables [Molecular Sieves] | 3 - 5 years | 1 - 2 years | |

| Life cycle of the plant | 20 - 25 years | 3 - 4 years | |

| Power Consumption | 18 - 20 kW | 20 – 22 kW | |

| Repair & Maintenance | Economical & Less nos. | Expensive & Huge Nos. | |

Applications:

Oxygen Include combustion, Oxidation, Fermentation & waste water treatment

Mainly uses:- Metal Cutting Metal Gas Welding and Brazing

- Hardening

- Cleaning & Melting application

- Waste and Water Treatment

- In food Industry to maintain fresh, natural colour

- Glass industries for furnace enrichment

- Paper and Pulp Industries for Oxy bleaching and delignification