Call Anytime

-

-

Send Email

sales@nitroairengineers.com

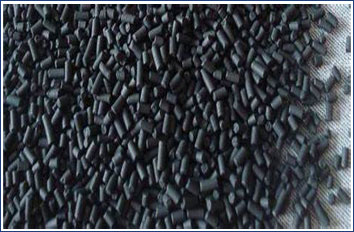

Carbon Molecular Sieve

Carbon Molecular Sieve (CMS) is a highly engineered material with unique properties that make it indispensable in a wide range of industrial applications. It is a form of activated carbon that has been modified to have an exceptionally high surface area and a precisely controlled pore size distribution. These characteristics enable CMS to selectively adsorb molecules based on their size, shape, and polarity.

Key Features and Benefits

High Adsorption Capacity: CMS exhibits an extraordinary adsorption capacity for small molecules such as oxygen, nitrogen, and carbon dioxide. This property is particularly useful in gas separation and purification processes.

Selective Adsorption: With its precisely controlled pore size distribution, CMS can selectively adsorb specific molecules while allowing others to pass through. This selectivity is instrumental in separating gases and creating high-purity products.

Rapid Adsorption/Desorption Kinetics: CMS demonstrates excellent kinetics, allowing for fast adsorption and desorption cycles. This characteristic is vital in applications where quick and efficient gas separation is required.

Thermal and Chemical Stability: CMS is highly stable under a wide range of temperatures and chemical environments, making it suitable for demanding industrial applications.

Applications of Carbon Molecular Sieve

Pressure Swing Adsorption (PSA) Systems: CMS plays a critical role in PSA systems used for gas separation and purification. It effectively separates gases, enabling the production of high-purity nitrogen, oxygen, hydrogen, and other gases.

Air Separation Units (ASU): In air separation processes, CMS is utilized to separate nitrogen from air, allowing for the production of high-purity oxygen. This is essential in various industries, including healthcare, metal fabrication, and wastewater treatment.

Biogas Upgrading: CMS is employed in biogas upgrading systems to remove impurities such as carbon dioxide, moisture, and trace contaminants from biogas. This enables the production of biomethane, a clean and renewable energy source.

Natural Gas Dehydration: CMS can efficiently remove water vapor from natural gas, preventing corrosion and maintaining the quality of the gas during transportation and storage

Hydrogen Purification: CMS plays a crucial role in purifying hydrogen gas by selectively adsorbing impurities such as water, carbon dioxide, and hydrocarbons. This ensures the production of high-purity hydrogen for various applications, including fuel cells and chemical processes.

At Nitroair Engineers Pvt Ltd. we are passionate about providing high-quality Carbon Molecular Sieve solutions tailored to your specific needs. With our deep expertise in advanced materials and a commitment to innovation, we offer reliable products that deliver exceptional performance and value.

Our team of experts works closely with clients to understand their unique requirements and provide comprehensive support throughout the project lifecycle. We are dedicated to delivering reliable products, outstanding customer service, and technical expertise to ensure your success.

Discover the limitless possibilities of Carbon Molecular Sieve for your industry. Contact us today to learn more about our products, request technical information, or discuss your specific application needs. We look forward to collaborating with you and helping you achieve your goals with Carbon Molecular Sieve.